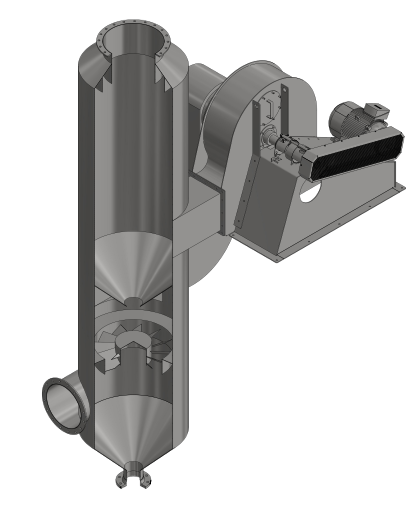

TREMA dynamic scrubber

TREMA dynamic scrubber are particularly used for the treatment of critical dust (hygroscopic, sticky etc.).

The exhaust air to be cleaned enters tangentially into the cylindrical lower part of the scrubber. The coarser particles are already separated here by means of centrifugal force.

The gas then flows through a fixed blade ring onto which a water fluid bed forms, in which another large proportion of the substances is separated.

In the second stage of scrubbing, the wet ventilator, whose impeller is centrally sprayed with scrubbing fluid, separation takes place in three ways:

1) The pollutants hit the wet impeller blades and are therefore bound to the scrubbing fluid.

2) The gas is powerfully accelerated radially outwards on the way by the fan axis. Because of the speed difference that occurs between the pollutants and the water droplets, the two components collide.

3)The gas / liquid mixture is swirled and broken up by the impeller. The pollutants bind themselves to the scrubbing fluid in this turbulence.

The cleaned gas is pushed tangentially into the demister together with the droplets loaded with pollutant. The droplets are flung against the wall by centrifugal force, from where they run downwards over the pre-cleaning zone and the scrubber cone into the circulation tank.

The cleaned exhaust gas exits the scrubber through a port in the upper part.